Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Blog Article

Why to Pick Industrial Scales for Accurate Weight Dimension in Numerous Industries

In an era where precision is extremely important, the selection of commercial ranges for exact weight dimension plays an important duty across diverse sectors. These ranges not only boost functional performance yet likewise ensure conformity with regulative criteria, influencing whatever from manufacturing to delivery. Their durable design and advanced innovation deal with various applications, reinforcing the demand for meticulous weight monitoring. Understanding the nuances of these ranges is important for any type of organization intending to maximize processes and reduce pricey errors. Yet, the concern remains: what certain variables should one take into consideration when choosing the right range for their one-of-a-kind operational requirements?

Importance of Accurate Weight Measurement

In the world of industrial operations, the relevance of precise weight dimension can not be overemphasized. Accurate weight dimension is fundamental across various industries, affecting both functional performance and item high quality - Industrial Scales. It works as an essential element in supply management, making sure that products are adequately represented, therefore minimizing waste and lowering prices

In manufacturing, exact weight dimension directly affects manufacturing procedures. Abnormalities in weight can bring about low-grade items or extreme source appropriation, affecting overall profitability. In addition, in markets such as pharmaceuticals and food manufacturing, adherence to stringent weight specifications is crucial for regulatory compliance and customer security.

In addition, precise weight measurements assist in efficient logistics and supply chain administration. Effectively evaluated deliveries ensure that transportation prices are enhanced which stock degrees are preserved properly, therefore preventing stock lacks or overstock scenarios.

Sorts Of Industrial Scales

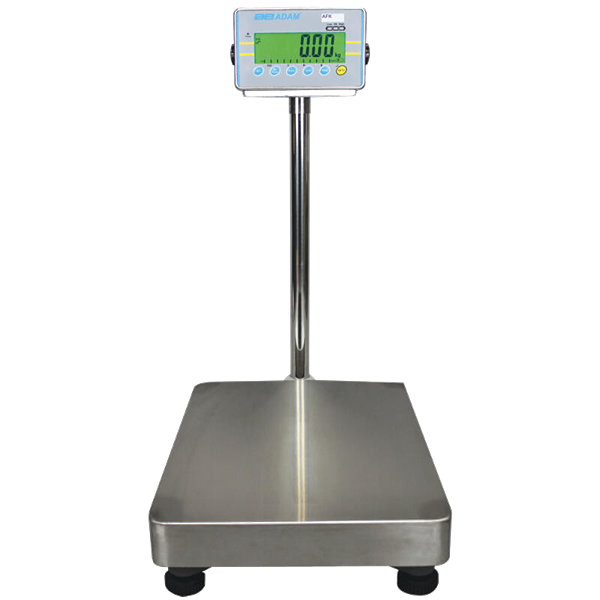

A wide array of industrial scales are offered, each created to meet specific measurement requires throughout diverse fields. Common kinds include flooring scales, which are durable and appropriate for evaluating big things or pallets in warehouses and distribution. Bench scales are smaller and excellent for lighter products, typically made use of in retail settings or producing for precise part control.

Another category is portable scales, which offer the adaptability to be moved quickly around work websites, making them perfect for field procedures or short-lived setups. Accuracy scales, on the various other hand, are made for high accuracy and are often used in research laboratories and top quality control settings.

Tons cells are crucial elements in various commercial ranges, converting force into an electrical signal for exact readings. In addition, truck ranges provide the ways to evaluate hefty lorries and their tons, guaranteeing compliance with guidelines and enhancing logistics.

Finally, checkweighers automatically compare the weight of items versus pre-programmed limits, improving top quality assurance in production lines (Industrial Scales). Each kind of industrial scale serves an unique feature, accommodating the certain demands of sectors such as manufacturing, logistics, food processing, and pharmaceuticals

Benefits of Making Use Of Industrial Scales

Regularly utilizing commercial scales uses substantial benefits across different fields. One of the main benefits is boosted accuracy in weight measurement, which is important for preserving high quality standards and regulatory compliance. Accurate dimensions stop pricey errors in manufacturing, shipping, and stock monitoring, inevitably leading to raised functional efficiency.

Additionally, industrial scales are designed for longevity and toughness, enabling them to endure severe environments usually located in manufacturing and warehousing. This durability ensures a lengthy lifespan, decreasing the demand for constant substitutes and maintenance expenses.

In addition, utilizing commercial ranges enhances safety and reduces waste. By making certain that items are considered properly, firms can stay clear of straining vehicles, which can bring about fines and crashes.

Applications Throughout Various Industries

Industrial scales play a pivotal function in many markets, consisting of manufacturing, logistics, food handling, and pharmaceuticals. In manufacturing, these scales are essential for guaranteeing that basic materials are gauged accurately, thus preserving product top quality and uniformity (Industrial Scales). Precision in weight measurement directly affects production performance and price administration

In logistics, industrial scales promote the accurate weighing of deliveries, which is crucial for adhering to delivering guidelines and maximizing freight costs. Exact weight data aids streamline procedures and boosts supply chain monitoring.

The food handling market depends heavily on commercial scales for compliance with health and wellness and safety laws. They are utilized to weigh ingredients precisely, ensuring that formulas satisfy both quality requirements and lawful demands. This is essential not only for customer safety however likewise for preserving brand name stability.

Drug business use commercial ranges to make certain accurate does in drug production, where also the tiniest inconsistency can have substantial repercussions. Compliance with rigid regulative standards makes exact weight measurement vital in this field.

## Factors to Think About When Choosing Scales

Selecting the right scale for details applications calls for mindful anchor consideration of numerous variables. The capability of the scale is crucial; it should suit the maximum weight of the items being gauged without exceeding its restrictions. Furthermore, the readability, or smallest increment the scale can properly display, is crucial for accuracy, specifically in industries where weight discrepancies can result in significant financial losses or safety problems.

Environmental conditions likewise play a substantial role in scale selection. Ranges made use of in corrosive or damp environments might need specific products to make sure toughness. In a similar way, portability may be crucial in specific applications, demanding light-weight and battery-operated versions.

Verdict

In verdict, the selection of industrial scales is crucial for making certain precise weight dimension across diverse markets. Hence, spending in high-quality industrial ranges is crucial for organizations aiming to preserve high criteria and maximize earnings.

Report this page